Case Study – Earth-Air Heat Exchanger Model

The challenge

Polypipe Civils have developed a range of reinforced polyethylene pipes for use as

earth-air heat exchangers. They and their partners WSP require a software tool to

calculate the heating and cooling benefits of a heat exchanger made from the pipes

hour-by-hour using hourly air temperature data for locations across the UK and for

a range of soil types.

The solution

Atkinson Science created a software tool for Polypipe Civils and WSP which

calculates hourly and yearly cooling benefits in seconds. The user interface is

intuitive and familiarisation takes only a few moments. The interface has six tabs

and the user works from left to right entering information into the tabs.

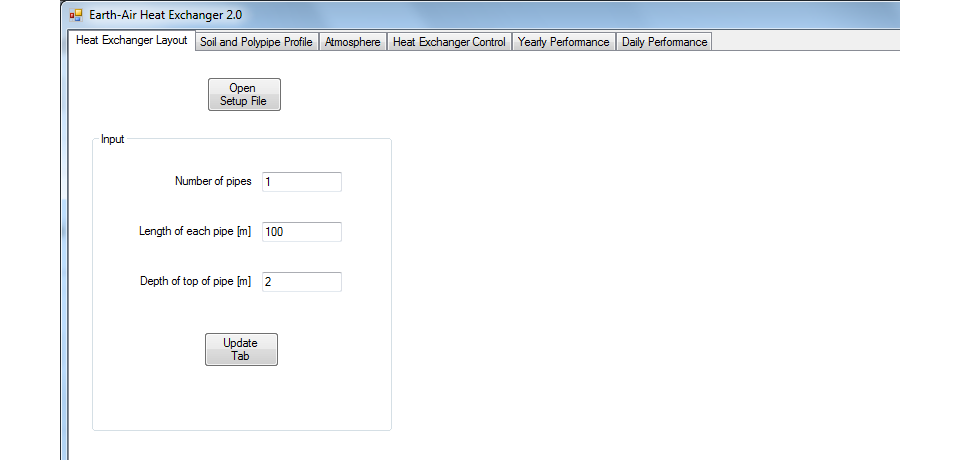

On the first tab (Figure 1) the user can either import a set-up file containing all

the information for a complete earth-air heat exchanger or begin a new design by

entering the length, depth and number of pipes. The user clicks the Update button

to save the information in computer memory.

Figure 1 Heat Exchanger Layout tab

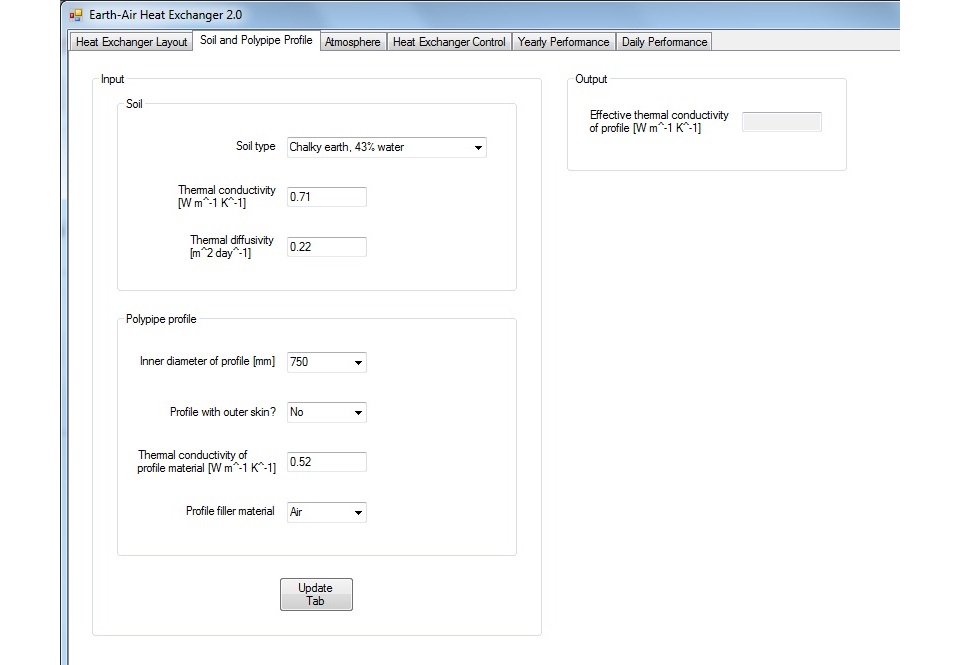

On the second tab (Figure 2) the user selects the soil type, the inner diameter of

the pipe from the Polypipe range, and the type of reinforcement around the outside

of the pipe. When the user clicks the Update button the software tool calculates

the effective thermal conductivity of the pipe and reinforcement.

Figure 2 Soil and Polypipe Profile tab

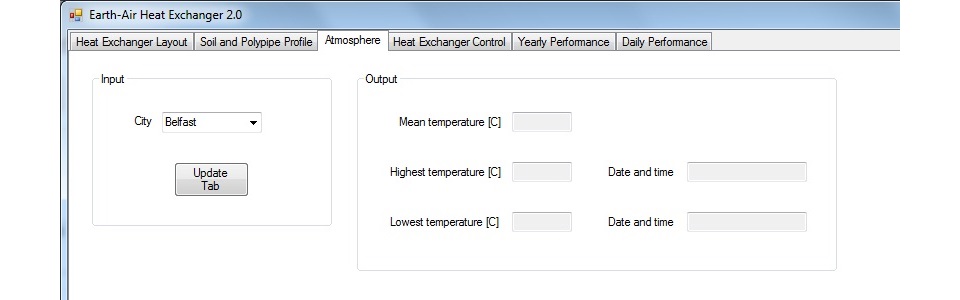

On the third tab (Figure 3) the user selects the hourly temperature data from a

database. The database contains data for thirteen cities across the UK. When the

user clicks the Update button the software tool reads in the hourly temperature

data for the chosen city and computes some basic statistics (the mean, maximum and

minimum air temperatures and the date and time at which the maximum and minimum

occur).

Figure 3 Atmosphere tab

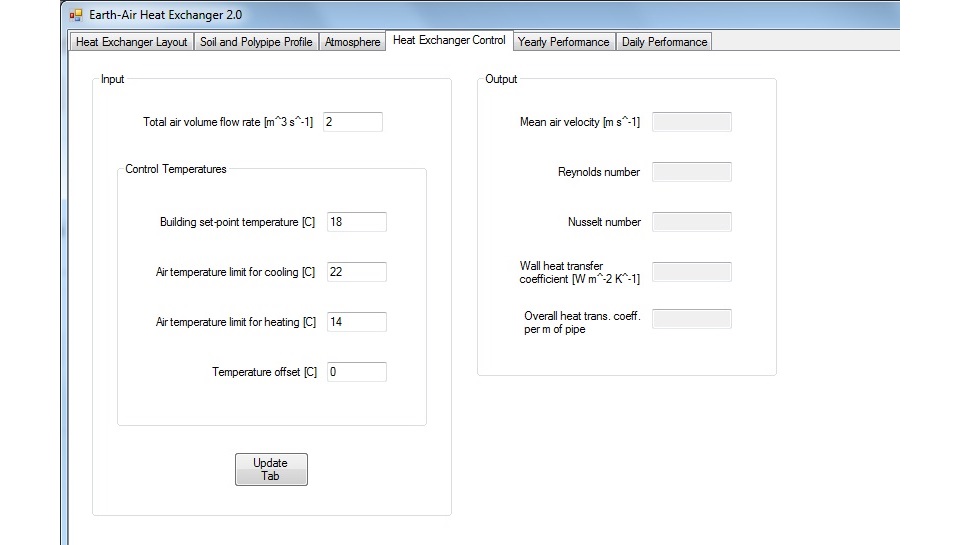

On the fourth tab (Figure 4) the user enters the air volume flow rate, the building

set-point temperature, and the rules by which the fan switches itself on or off in

accordance with the set-point temperature, the atmospheric air temperature and the

heat exchanger outlet temperature. When the user clicks the Update button the

software tool calculates some basic flow and heat transfer information, such as

the Reynolds number and the Nusselt number of the pipe flow and the wall heat

transfer coefficient.

Figure 4 Heat Exchanger Control tab

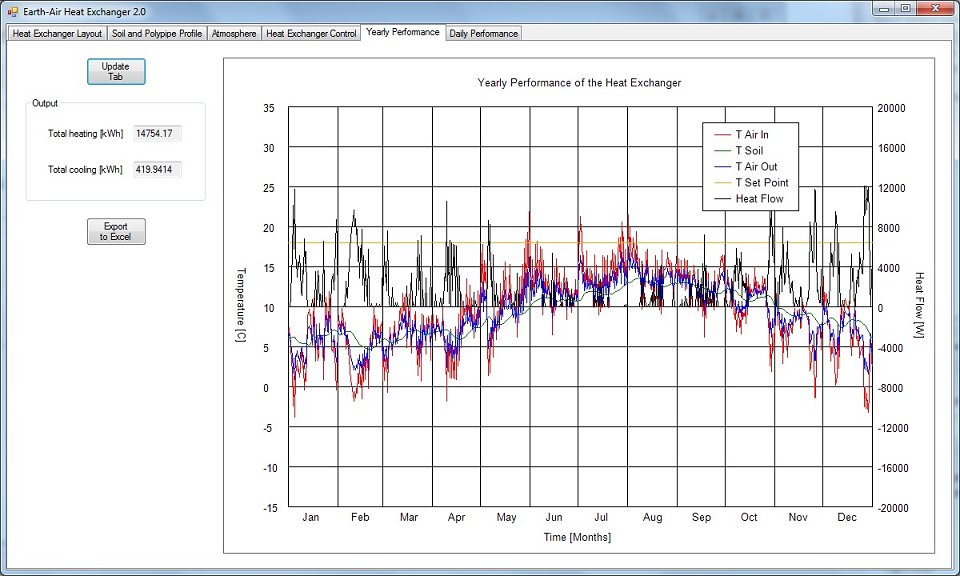

The fifth tab (Figure 5) displays the yearly performance of the heat exchanger.

When the user clicks the Update button the software tool uses the input entered

into the previous tabs to calculate the soil temperature, the air outlet

temperature, and the total heat flux to or from the heat exchanger hour-by-hour

for a whole year. The tool integrates the heat flux over periods of heating and

cooling to give the heating and cooling benefits in kWh and displays them in two

text boxes.

Most of the area of the tab is taken up with a chart displaying curves of

temperature and heat flux. The air inlet temperature is indicated by the red

curve, the soil temperature by the green curve, the air outlet temperature by the

blue curve, the building set-point temperature by the orange horizontal line, and

the heat flux by the black curve. If the control criteria entered on the fourth

tab cause the heat exchanger to switch off at any time then the black curve will

go to zero. However, the air outlet temperature will continue to be calculated and

displayed as the blue curve as though the heat exchanger were still operating. By

continuing to display the blue curve during these periods the user will be able to

see that the change in air temperature through the heat exchanger does not justify

its use.

Figure 5 Yearly Performance tab

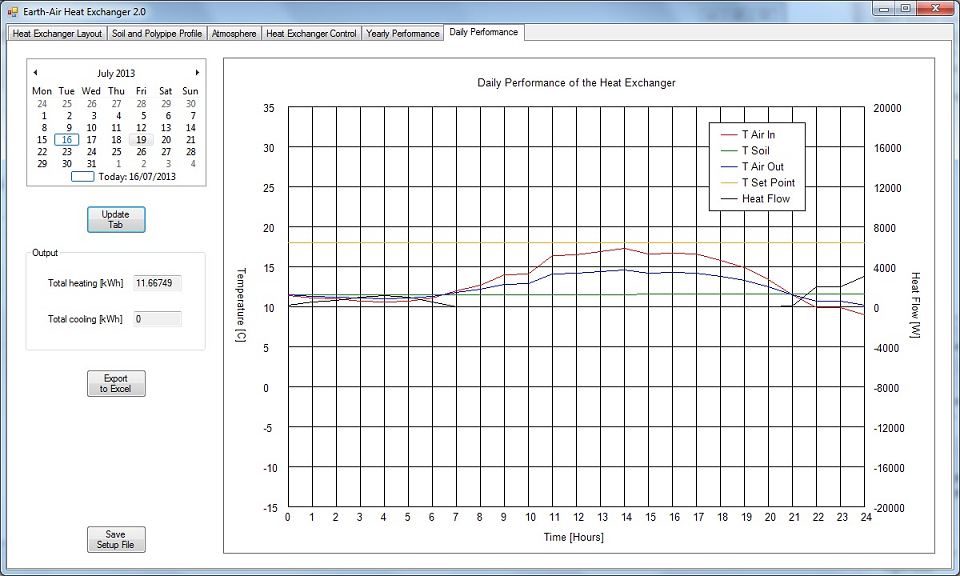

The sixth tab (Figure 6) displays one day’s worth of data out of the 365 days of

data already computed. The user selects the date from a calendar and clicks the

Update button to display the data on a chart. The heating and cooling benefits in

kWh over the 24-hour period are displayed in two text boxes.

Figure 6 Daily Performance tab

The benefits

The software tool enables Polypipe Civils and WSP to design an earth-air heat

exchanger based on Polypipe’s reinforced pipes, set the criteria to control its

operation, and calculate the heating and cooling benefits hour-by-hour when it is

operational. By comparing these benefits with the running costs of the heat

exchanger and the cost of installation and maintenance they can determine whether

the heat exchanger is a worthwhile investment.