Case Study – Infiltration in a Book Storage Warehouse

The challenge

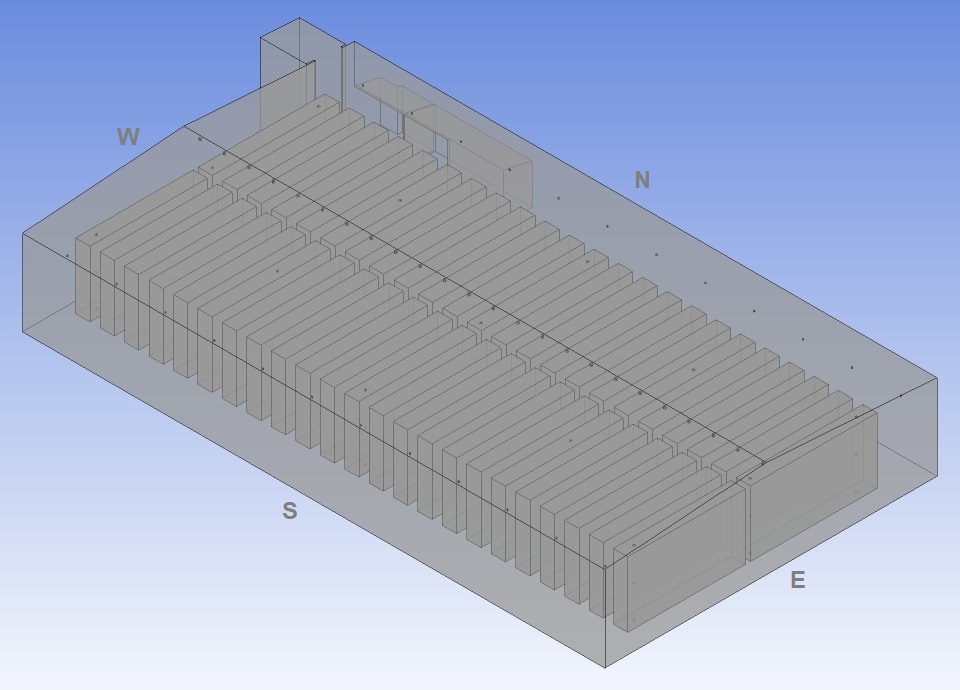

The University of Cambridge plans to move its large collection of books from

numerous small storage facilities to a new large book storage warehouse. The floor

plan of the main storage hall will be 87 m × 51 m and there will be two banks of

23 shelving bays 10 m tall. The ventilation system will consist of high-level

diffusers along opposite sides of the warehouse and extract grilles just below the

apex of the roof. The designers must provide evidence that the atmosphere in the

warehouse will be maintained between 13-20°C and 35-60% RH whatever the number of

books or the way they are stored or the external environment. The air permeability

Q50/Sp of the warehouse is expected to be

1 m3 h−1 m−2 at 50 Pa, which is better than the

best practice value for industrial buildings of

3.5 m3 h−1 m−2 at 50 Pa.

The solution

Atkinson Science used state-of-the-art computational fluid dynamics (CFD) software

to create a CFD model of the warehouse. We made an initial series of computations

without infiltration with the warehouse going from being empty to being full and

we considered different ways of arranging the books on the shelves as the

warehouse filled up. We believe we challenged the ventilation system sufficiently

to be able to say that it will perform satisfactorily however full the warehouse

or whatever the arrangement of the books or whatever the external environment. In

all of the computations the temperature and relative humidity in the warehouse

were well within the specified limits.

CFD model

If the joints between the walls and the roof and the walls and the floor are not

sealed properly the warehouse will be vulnerable to infiltration due to the stack

effect during the winter and summer months. Cold, dry air will enter the warehouse

at floor level in winter, and warm, moist air will enter the building at roof

level in summer. We used the CFD model to determine the risk to the shelving bays

in winter and summer. We calculated the effective leakage area based on the air

permeability target of 1 m3 h−1 m−2 at 50 Pa and

we assumed that half the leakage area occurred along the joint between the east

wall and the floor and the other half occurred along the joint between the south

wall and the roof.

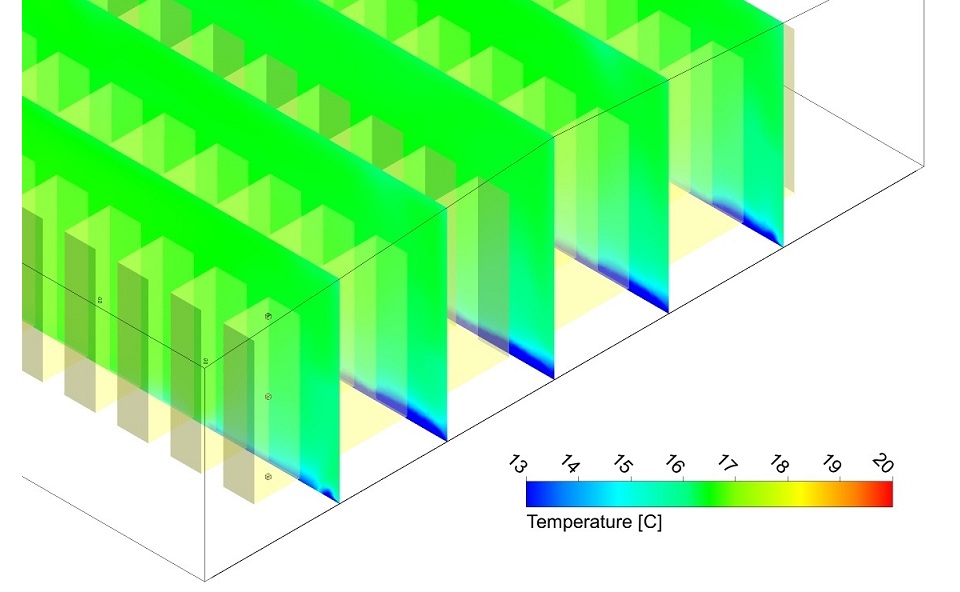

The figure below shows the temperature along the joint between the east wall and

the floor at the coldest time of the day in February. In regions coloured blue

the temperature is at or below the specified lower limit of 13°C. The cold air

entering the warehouse does not disperse, but spreads along the floor because it

is heavier than the surrounding air. It reaches the two shelving bays nearest to

the east wall and cools the books on the lowest shelves to below the lower

temperature limit. The relative humidity of the cold air is above the specified

upper limit of 60%, so the books on the lowest shelves are enveloped in air that

is too cold and too humid. The result shows that infiltration can cause breaches

in the temperature and humidity specification even when the air permeability of

the building is very low. To prevent such breaches, not only must the air

permeability be low, but the joint between the walls and floor must be sealed

properly.

Infiltration along the floor

In summer the stack effect operates in reverse. Warm, moist air enters the

warehouse through the opening between the south wall and the roof while air at the

set point leaves through the opening between the east wall and the floor. The

infiltration is lighter than the air in the warehouse, so it simply collects at

the apex of the roof and does not affect the environment around the shelving

bays.

The benefits

Atkinson Science showed that the proposed ventilation system will perform

satisfactorily regardless of the number or arrangement of books in the warehouse

or the external environment, provided the warehouse is sealed properly. We showed

that even when the air permeability of the building is very low, the temperature

and humidity specifications can be breached in winter if the joint between the

external walls and the floor is not sealed properly. We approved the ventilation

system provided that the seal between the external walls and the floor was checked

for leakages during the first winter of operation while the warehouse was still

empty and that any cracks were filled.