Case Study – Infiltration in a Raw Materials Warehouse

The challenge

A warehouse contains raw materials used in the manufacture of pharmaceutical

products. The temperature in the warehouse must remain between 17°C and 25°C and

the relative humidity must remain between 35% and 65%. A measurement survey showed

that in winter the lower temperature and humidity limits were being breached at

the bottom of the storage racks close to the east corner of the warehouse.

Draughts of cold air could be felt at floor level in this corner. The

air-conditioning system was becoming dilapidated. The warehouse owner needed to

know whether the air-conditioning system was (a) no longer working properly and

in need of replacement or (b) perfectly serviceable and being overwhelmed by a

leaky building. Atkinson Science was asked to devise a programme of testing and

computations to determine the most cost-effective way of bringing the warehouse

back into compliance with the T and RH specifications.

The solution

Atkinson Science devised a programme of work designed to show whether the existing

air-conditioning system was simply being overwhelmed by infiltration. If a

building is very leaky then replacing the air-conditioning system may produce no

benefit and be a costly mistake. The programme consisted of:

- A leakage survey to identify potential leakage paths into the warehouse;

- An air-tightness test conducted by BSRIA to determine the characteristic

leakage curve of the warehouse;

- Estimation of the location and extent of leakage flows from the results of

(a) and (b);

- Creation of a CFD model of the warehouse incorporating the leakages and the

existing air-conditioning system. Validation of the model using the results of

the measurement survey;

- Using the validated model to see whether a proposed new system would make an

improvement when faced with the leakages.

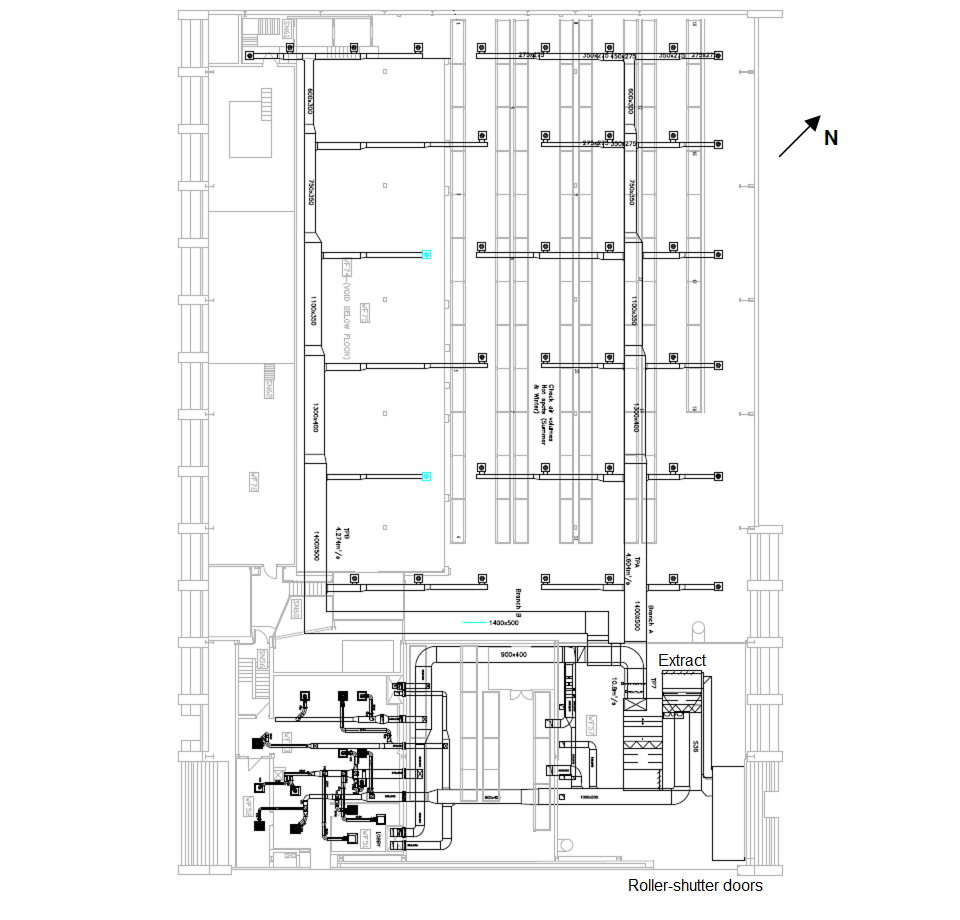

The warehouse is shown in plan view in Figure 1. The warehouse has a floor area of

54 m × 38 m and a height of 10 m. The storage racks occupy only a third of the

floor area. The rest of the space is taken up with offices. The storage area is

ventilated by high-level diffusers, which are shown in Figure 1. There is a single

extract vent, which is also shown. Goods are moved in and out of the warehouse

through the roller-shutter doors at the east corner of the warehouse. The leakage

survey identified numerous potential leakage sites. However, there were two sites,

in particular, that were draughty and were clearly allowing in large volumes of

air. The first was the join between the northeast wall and the concrete floor and

the second was the bottom of the roller-shutter doors. The air-tightness test

returned an air permeability Q50/Sp of 6.74

m3 h−1 m−2. According to CIBSE TM23:2000, this

value represents good practice for large industrial buildings, but not best

practice, which would require Q50/Sp to be

3.5 m3 h−1 m−2 or less. From the characteristic

leakage curve the effective leakage area (EFA) was found to be

1.07 m2.

Fig 1 Plan of the raw materials warehouse

Leakages into a building can be caused by wind pressures on the building or by the

difference in the internal and external temperatures (the stack effect). The stack

effect will be greatest in winter and summer when the temperature difference is

greatest and the taller the building the greater the stack effect. In winter, cold

air will enter the building through openings at low level and warm air will leave

through openings at high level. The draughts in the east corner of the warehouse

were at floor level and were detected on a calm day in January, so we concluded

that the draughts were being caused by the stack effect. The measurement survey

showed that in winter the lower temperature and humidity limits were being

breached at the bottom of the storage racks close to the East corner of the

warehouse. These breaches are consistent with our conclusion that cold air was

entering the warehouse at floor level under the stack effect.

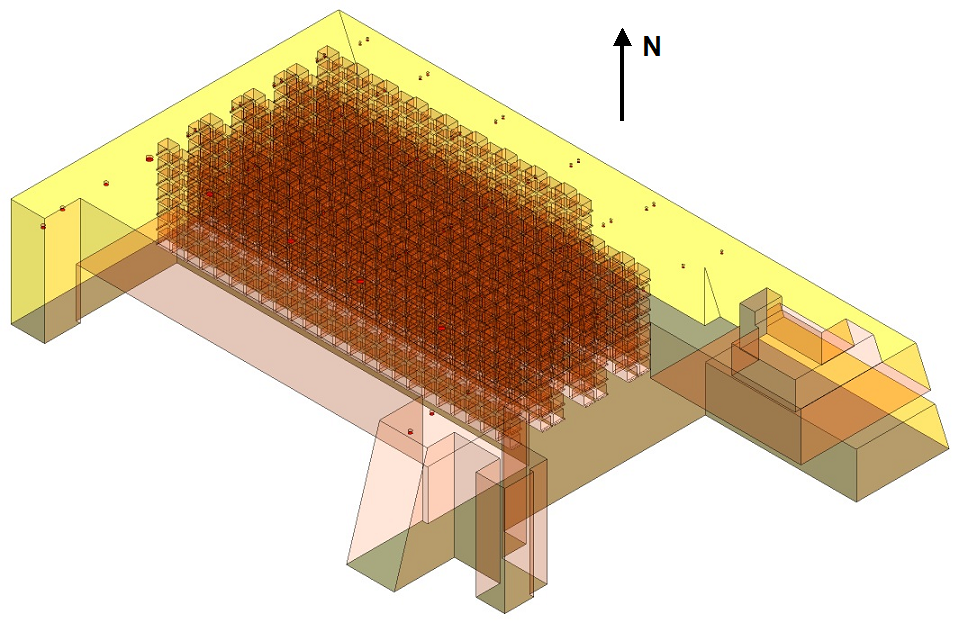

We built a CFD model of the warehouse with the ventilation provided by the existing

system. Figure 2 shows the computational domain. We distributed half the leakage

area along the bottom of the northeast wall and the bottom of the roller-shutter

doors and half along the wall at roof level. Assuming there was no wind pressure

on the building, we calculated that 2.1 kg s−1 of air was entering the

warehouse at low level and leaving at high level. Over the two-week period of the

measurement survey the lowest outside temperature measured was −6.6°C. The

relative humidity measured at the same time was 98.6%. We used these values as

external boundary conditions.

Fig 2 Computational domain

The ventilation system supplies 10.7 m3 s−1 of conditioned

air. A CFD computation involves an iterative process. At the end of each iteration

we adjusted the supply temperature so that the computation achieved the measured

average temperature in the warehouse (20.5°C). Then we adjusted the supply

relative humidity so that the computation achieved the measured average relative

humidity (38.3%). At the end of the computation the supply conditions were 26.8°C

and 29.0% RH.

In winter the moisture content of the outside air is very low compared with the

moisture content in the warehouse. At the outside conditions, −6.6°C, 98.6% RH,

the moisture content is 2.12 g kg−1 dry air and at the average inside

conditions, 20.5°C, 38.3% RH, the moisture content is 5.73 g kg−1 dry

air. Consequently, we can easily identify the location of the leakage air in the

warehouse by the drop in moisture content.

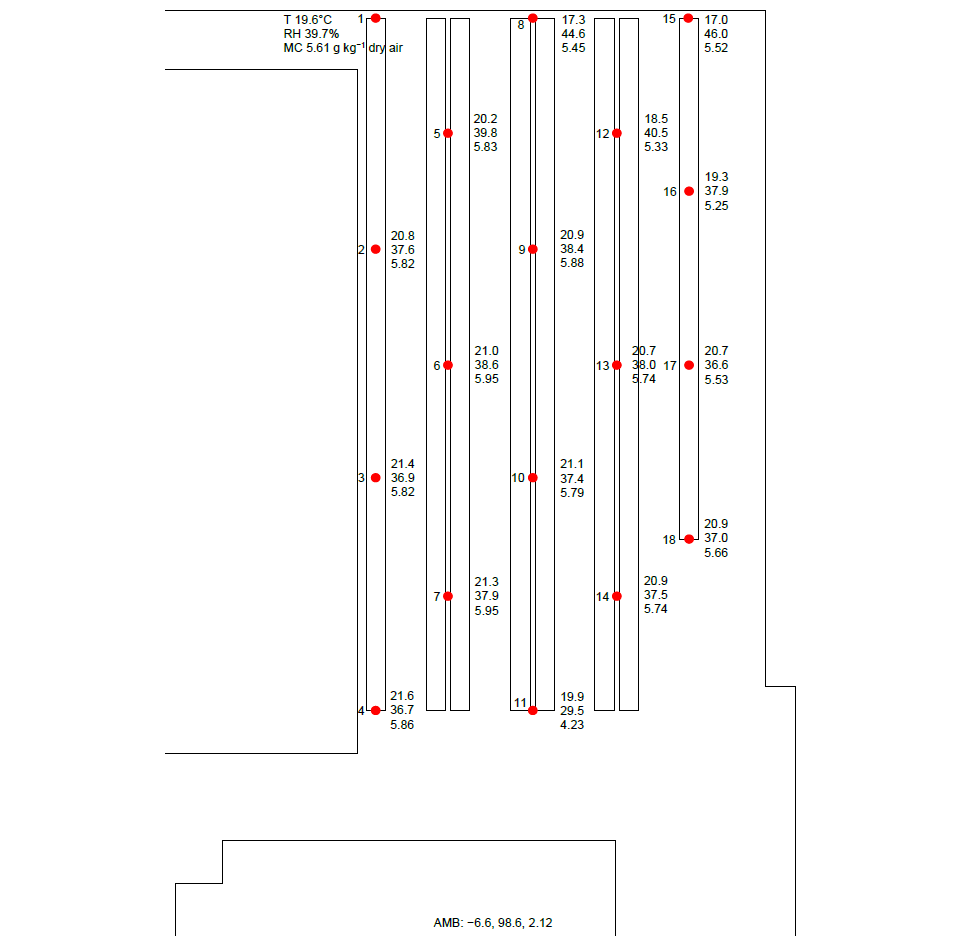

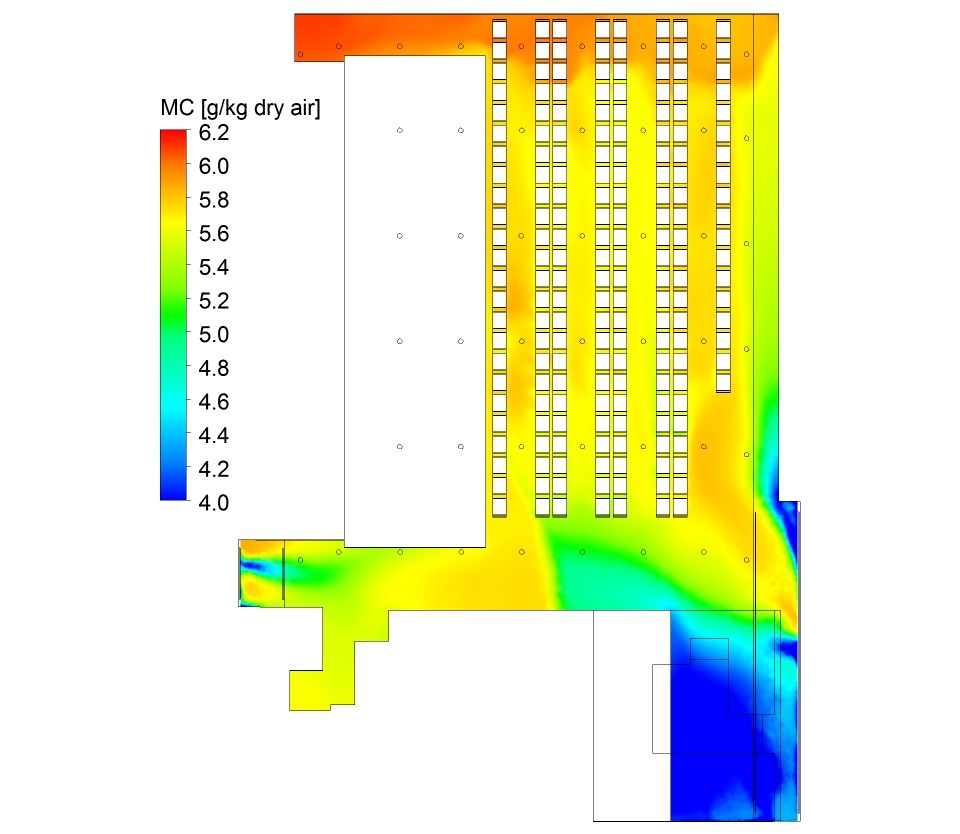

For the measurement survey the warehouse contained 54 T/RH loggers arranged in

columns of three at the top, middle and bottom of the storage racks. Figure 3

shows the location of each column and the readings of the bottom loggers when the

outside conditions are −6.6°C, 98.6% RH. We have also added the moisture content,

calculated from the measured T and RH values. The highest temperatures are

recorded in the storage rack closest to the office block and the temperature falls

gradually towards the north and east corners of the warehouse. The average

moisture content over the bottom loggers is 5.61 g kg−1 dry air. At

location 11 in Figure 3 the moisture content falls to its lowest value of

4.23 g kg−1 dry air. We can show that the warehouse air must contain

22% by volume of outside air for the moisture content to fall from the average

value to this value. Location 11 is the closest to the northeast wall and the

roller-shutter doors where the draughts were felt.

Fig 3 Measured T, RH and moisture content

for the bottom loggers

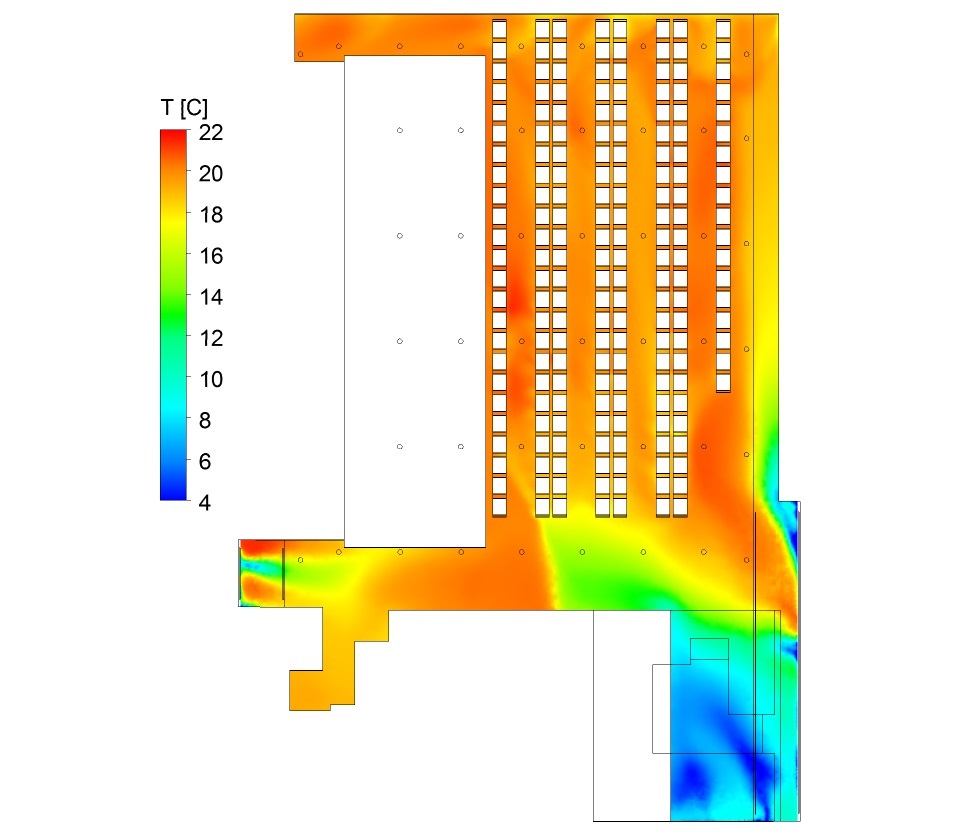

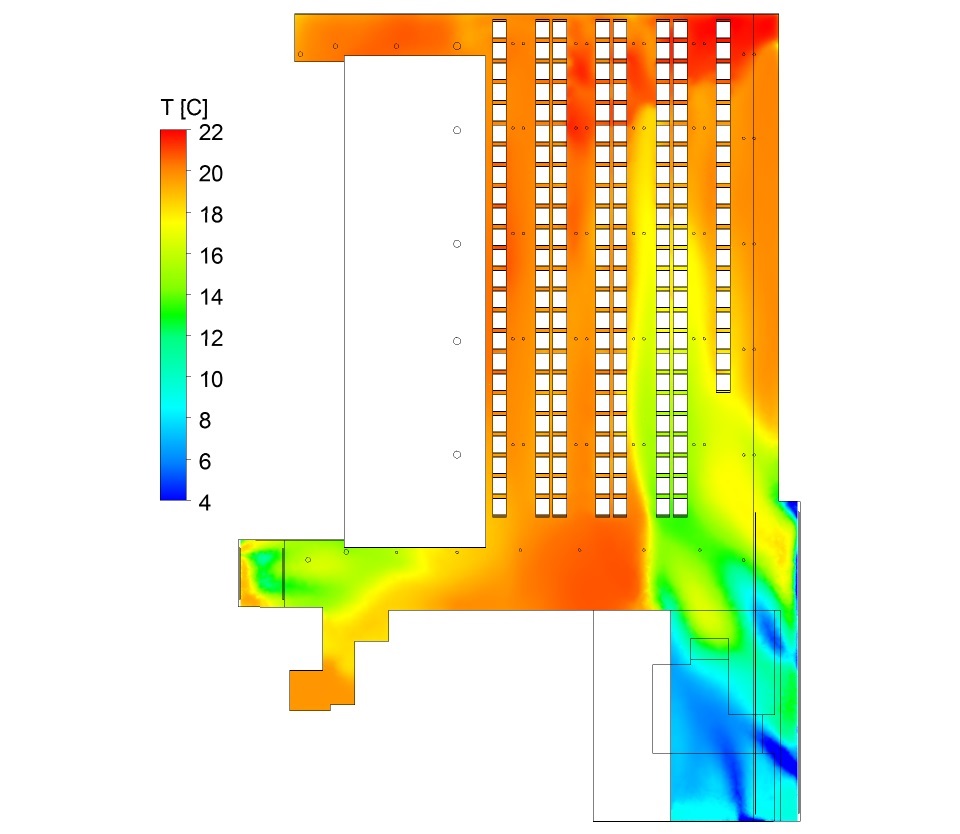

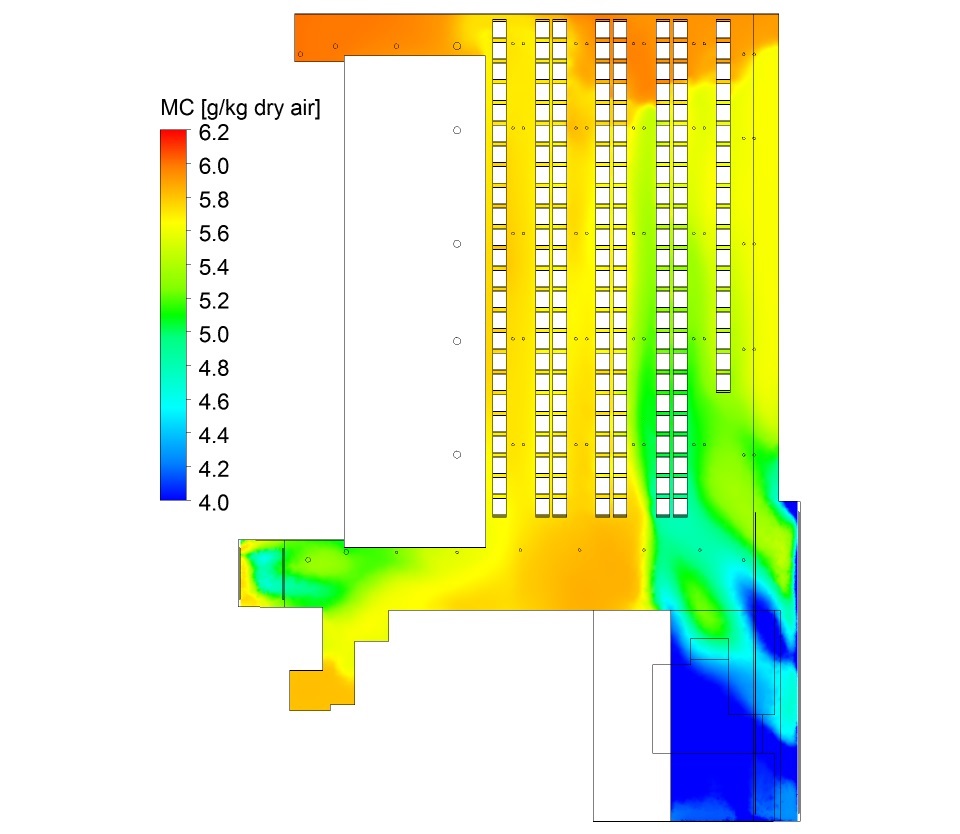

Figures 4 and 5 give the temperature and moisture content computed by the CFD model

in the same plane as the bottom loggers. A large swathe of cold air can be seen

moving from the east corner of the warehouse towards the storage racks. However,

the lowest moisture content in any of the racks (5.35 g kg−1 dry air)

occurs at the end of the second rack from the office block, 4 metres from

location 11. The computation is consistent with the measurements, but more of the

infiltration flows across the front of the racks and less down the aisles between

the racks. The average computed moisture content over the bottom loggers is

5.71 g kg−1 dry air, which compares well with the average measured

value of 5.61 g kg−1 dry air. From these comparisons, we can conclude

that we have specified the location and amount of infiltration reasonably well and

that the CFD model provides an accurate representation of the temperature and

humidity when the existing ventilation system is opposed by the infiltration.

Fig 4 Computed temperature in the plane of

the bottom loggers for the existing air-conditioning system

Fig 5 Computed moisture content in the plane

of the bottom loggers for the existing air-conditioning system

We used the validated CFD model to determine how a proposed new ventilation system

would perform when faced with the same infiltration. The proposed new system

consists of 62 high-level diffusers supplying 10.7 m3 s−1

of conditioned air. At the end of the CFD computation the supply conditions were

27.3°C and 28.2% RH. Figures 6 and 7 show the computed temperature and moisture

content in the same plane as the bottom loggers. Comparing Figures 4 and 6 shows

that the temperature around the storage racks is less uniform with the new system,

and especially around the racks on the northeast side of the warehouse. Comparing

Figures 5 and 7 shows that more of the cold air is able to pass between the racks

than before. In fact, there is a build-up of temperature in the north corner of

the warehouse as warm air between the racks is pushed back by the flow of cold

air. The average measured temperature over the bottom loggers is 20.2°C. When the

existing system is replaced with the new system the average computed temperature

falls from 19.9°C to 19.2°C because warm air is displaced upwards by the cold air.

Clearly, the new system is less effective at dispersing the infiltration than the

existing system. In fact, it is difficult to imagine any high-level ventilation

system being able to disperse the cold air moving along the floor and we concluded

that the warehouse must be sealed before deciding whether to replace the existing

air-conditioning system with a new one.

Fig 6 Computed temperature in the plane of

the bottom loggers for the new air-conditioning system

Fig 7 Computed moisture content in the plane

of the bottom loggers for the new air-conditioning system

The benefits

The programme of work by Atkinson Science showed that the warehouse must be sealed

along its east side before any decision is made about replacing the

air-conditioning system. It is possible that the existing system will perform

perfectly well once the warehouse is sealed and that it would be more

cost-effective to undertake some simple remedial work on the system than to

replace it with a completely new system.