Case Study – Fume Dispersion from an Industrial Unit

The challenge

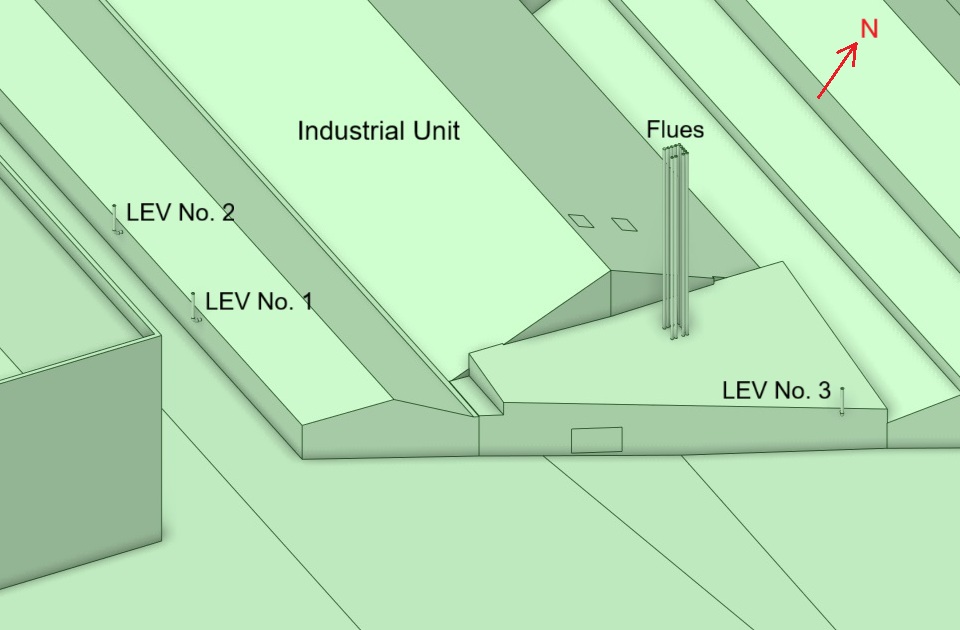

The University of Birmingham is refitting a single-storey industrial unit on the

Tyseley Energy Park so that it will become a manufacturing unit that will

discharge gaseous waste products to the atmosphere (Figure 1). There will be

eleven flues on the roof of the building, discharging a particular gas, either

nitrogen, hydrogen or argon. In addition, there will be outlets from three LEVs

that will discharge trace quantities of waste products. To be safe the pollutants

must rise clear of the industrial unit and other buildings, given the wind

conditions expected over the Energy Park.

Fig 1 Industrial Unit

The solution

Atkinson Science created a CFD model of the industrial unit and the surrounding

buildings and trees within 300 m of the unit. We used the model to calculate the

dispersion of the pollutants at three wind speeds (0.25, 2.5 and

10 m s−1) with the wind from the north and every 45° from the north.

All three gases from the flues are asphyxiants because they can displace the

oxygen in the air. In this study we were quite conservative and assumed that the

air will only become safe to breathe when the oxygen concentration returns to

20.8% by volume (compared with 20.95% in atmospheric air). A volume of a pollutant

gas must be diluted with 142 equal volumes of air to achieve this oxygen

concentration. This amount of dilution is more than enough to prevent hydrogen

from becoming a combustion risk.

The LEVs discharge pollutants in trace amounts below the long-term exposure limit.

They can present a risk if there is an accidental spill of a pollutant. There is

no official figure for the number of dilutions that an LEV system must produce,

but we would expect a well-designed system to produce a minimum of 100 dilutions.

This number of dilutions would safeguard against a surge in pollutant

concentration of two orders of magnitude.

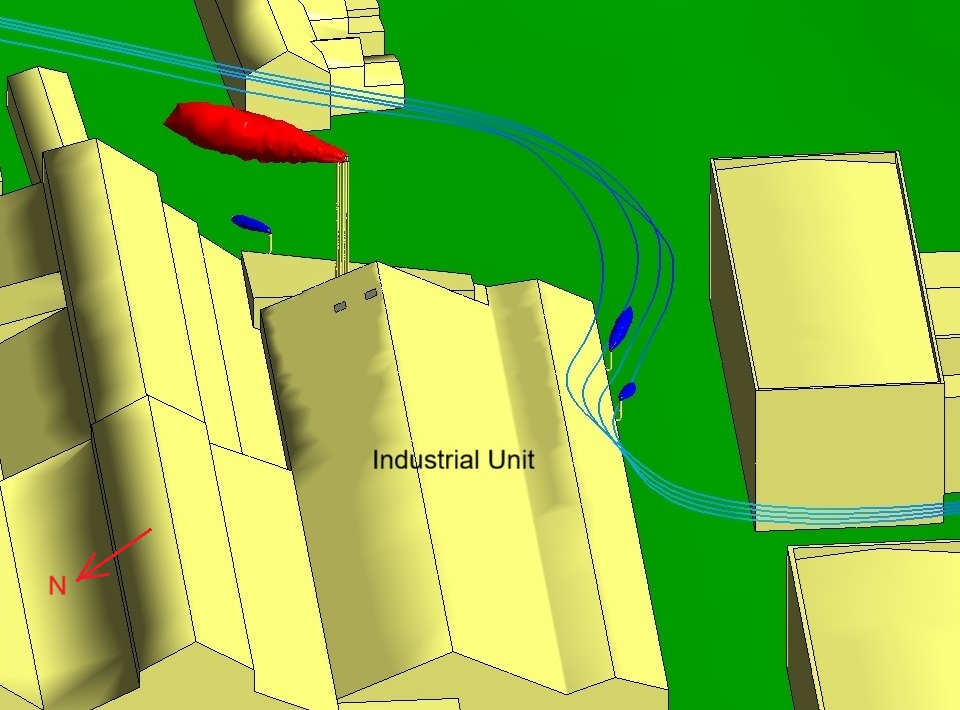

For each wind condition, we plotted the isosurface representing an oxygen

concentration of 20.8% by volume, and for each LEV, the isosurface representing

100 dilutions of the pollutants. We found that none of the isosurfaces came into

contact with a building or the ground at any of the wind conditions. At some wind

conditions the presence of a two-storey building to the south of the industrial

unit complicated the air flow onto the unit and made the discharge from two of the

LEVs change direction, as shown in Figure 2. However, the pollutants dispersed so

rapidly that there was no risk to safety.

Fig 2 Isosurfaces and streamlines for a

southwest wind at 10 m s−1

The benefits

The CFD study demonstrated to the University of Birmingham that the pollutants

discharged from the industrial unit will disperse safely into the atmosphere at

the wind conditions likely to occur on the Energy Park.