Case Study – Flight Simulator Building

The challenge

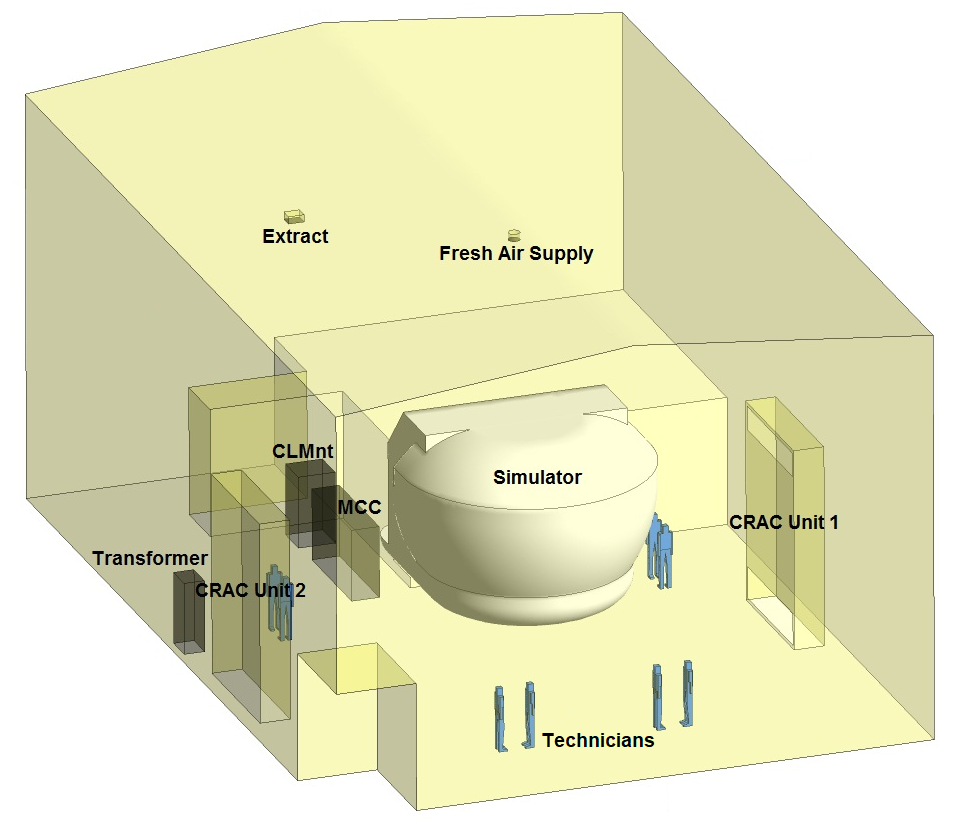

A building is being constructed to house a flight simulator similar to the one

shown in Figure 1. The building will be 12 m high and the simulator will be 8 m

tall at its highest point. The air temperature all around the simulator must be

maintained at 18 – 24°C. A design consultancy has devised an air-conditioning

system based on two up-flow computer room air conditioning (CRAC) units. The

consultants must demonstrate that the temperature will remain within the

specification on a hot summer’s day when the outdoor temperature is 29°C and on a

cold winter’s night when the outdoor temperature is −6°C. Apart from the flight

simulator, the building will contain ancillary equipment and up to eight

technicians. In summer the total sensible heat gain will be 71 kW and in winter

the total sensible heat loss will be 27 kW. Each CRAC unit can provide 91 kW of

sensible cooling at an air flow rate of 7.5 m3 s−1. There is

more than enough cooling capacity from one CRAC unit alone to offset the heat gain

in summer and the consultancy intend to operate one unit at 80% of its maximum

flow rate and leave the other unit on stand-by.

Fig 1 Flight simulator

The solution

Atkinson Science created a CFD model of the flight simulator building, as shown in

Figure 2. The CRAC units are labelled CRAC Unit 1 and CRAC Unit 2 in the Figure.

The appropriate fabric heat gain for summer or heat loss for winter was applied to

the outer surface of the model and the relevant heat gains were applied to the

outer surfaces of the flight simulator, ancillary equipment, etc. It is more usual

to have all available CRAC units in operation, but at part-duty, rather than to

have one or more CRAC units standing idle. Consequently, we calculated the

temperature in the building under summer and winter conditions, first with only

CRAC Unit 1 operational, then with only CRAC Unit 2 operational, and finally with

both CRAC units operational. We reduced the air flow rate from each unit to 70% of

the maximum when both units were operational.

Fig 2 CFD model

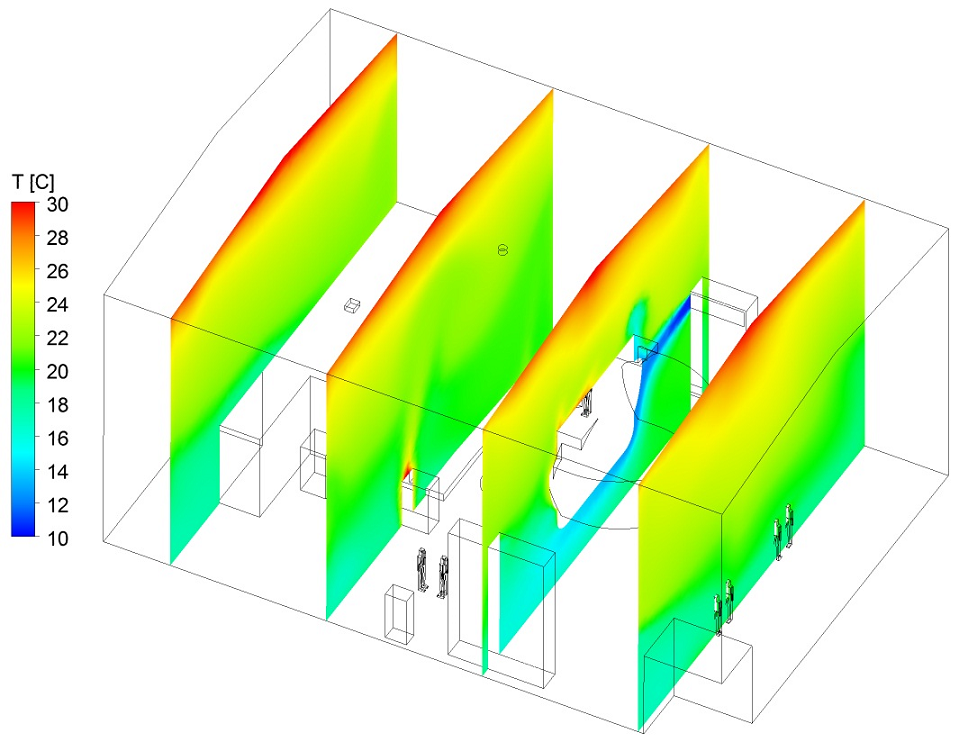

Figure 3 shows the temperature in the building in summer with CRAC Unit 1

operational and CRAC Unit 2 on stand-by. The temperature is stratified as is usual

at the height of summer. Warm air accumulates below the roof but the temperature

is within the specification of 18 – 24°C everywhere else. Unfortunately, the jet

of cool air from the CRAC unit impinges on the flight simulator and is forced to

pass under the simulator causing a temperature drop of 3 – 4°C in the occupied

zone below 2 m that will almost certainly be felt by the technicians. Much the

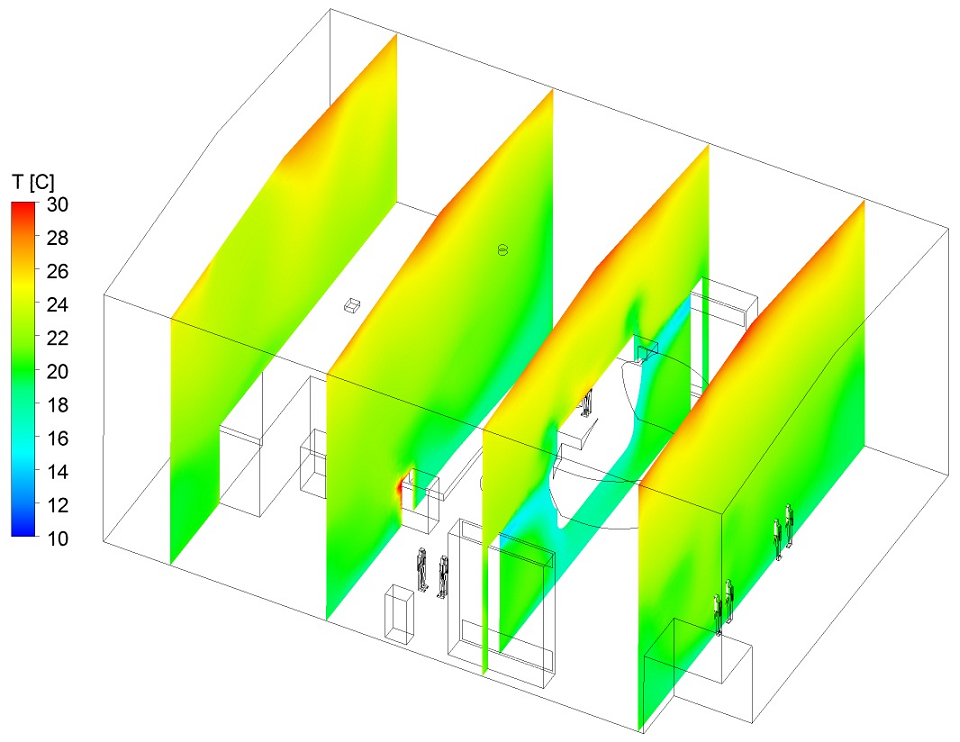

same happens when the operational CRAC unit is switched from 1 to 2. Having both

CRAC units operational makes the temperature drop all but disappear, as shown in

Figure 4, and the temperature is well within the specification around the flight

simulator.

Fig 3 Temperature for the summer period with CRAC Unit 1 operational

Fig 4 Temperature for the summer period with both CRAC units operational

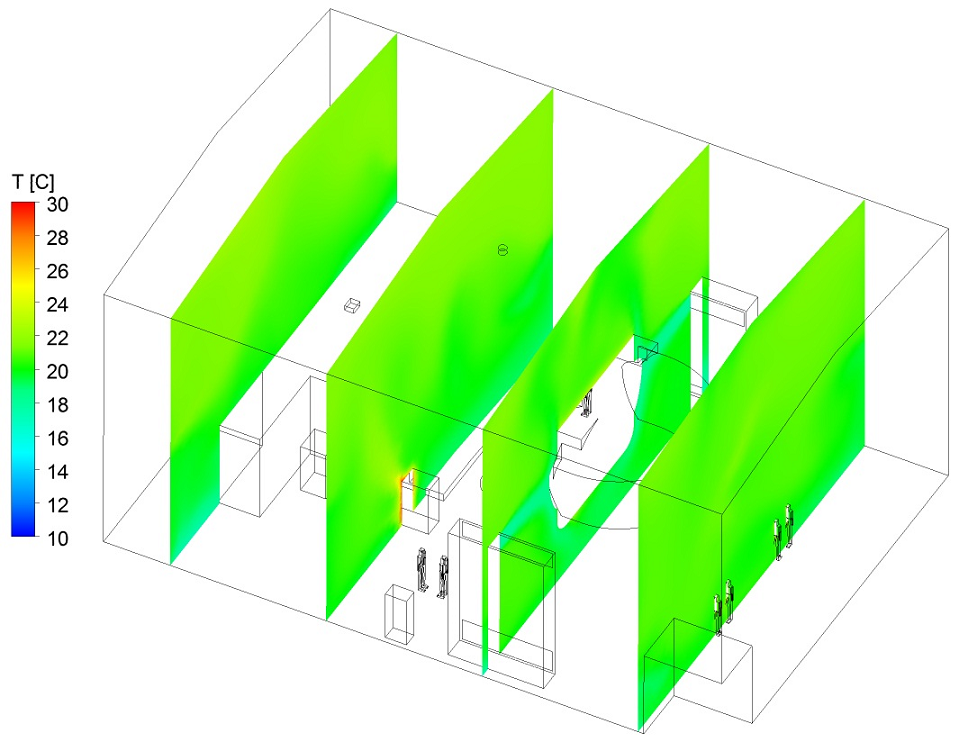

Figure 5 shows the temperature in the building in winter when both CRAC units are

operational. There is now very little stratification because the heat load in the

building is so much lower than in summer. Switching to only one operational CRAC

unit causes differences in temperature of no more than 0.7°C and the temperature

in the occupied zone is essentially uniform whatever configuration is used.

Fig 5 Temperature for the winter period with both CRAC units operational

Having one CRAC unit operational gives perfectly acceptable conditions in winter

but not in summer because this configuration creates a temperature drop in the

occupied zone that will be felt by the technicians. Consequently, our computations

led us to recommend having both CRAC units operational at part-duty. Having only

one unit operational is always likely to produce poorer ventilation because the

unit generates a greater concentration of negatively buoyant air. If the air flow

rate is decreased, for example by adding a filter to the unit, then the air may

slump to the floor and the mixing needed for good ventilation may not occur.

The benefits

Atkinson Science were able to provide the evidence the consultancy needed to show

that its proposed air-conditioning system would meet the temperature specification

when put into practice, but we also recommended a change in the proposed system by

having both CRAC units operational rather than only one operational and the other

on stand-by.